Products

Categories

New Products

Brand:

LMSitem no.:

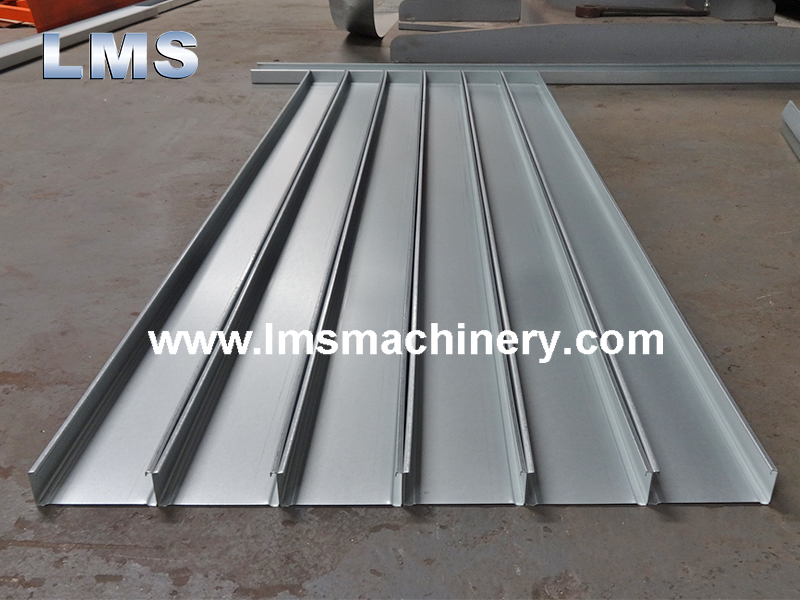

Stud And TrackPayment:

T/Tproduct origin:

ChinaColor:

Customizedshipping port:

HuangPu, GuangzhouLead Time:

90 Days

LMS Drywall Partition Stud And Track Production Line is mainly used for the production of drywall partition stud and track. The full production line includes manual decoiler, roll forming machine, flying cut-off device, run-out table and control system. The maximum production speed from decoiling to discharging could be about 100 meters per minute. Other revelant metal ceiling machines could be customized as well, welcome to send samples or drawings for customization.

1. Material: G.I. Coil / CR Coil

2. Material Thickness: According To Customer’s Requirement

3. Profile Width: According To Customer’s Requirement

4. Profile Height: According To Customer’s Requirement

5. Whole Production Line Speed: 60 - 70 Meters / Minute, Could Be Up To 100 Meters Per Minute.

Material Coil - Decoiling - Roll Forming (- Flying Punching) - Flying Cutting Off - Finished Profile.

| NO. | Equipment | Specification | Qty. |

| 1 | Manual Decoiler |

(1) Inner Diameter: Ø 460 - 510 MM (2) Loading Capacity: 1000 KGS (3) Manual Operating Type: Manual Expansion To Tighten The Coil |

1 Unit |

| 2 | Roll Forming Machine |

(1) Quantity Of Rollers: 12 Groups (2) Roller’s Material: Cr12 Steel, Heat Treatment, Quenched (3) Roller’s Surface Treatment: Polished (4) Roller’s Main Shaft: Ø 40 MM, 40 Cr Steel, Quenched & Heat Treatment (5) Bearing: HRB Bearing, Best In China (6) Machine Side Wall: 25 MM (7) Machine Base: Welded By 80 Square Pipe (8) Driving Method: Chain & Gear Or Gearbox (9) Coolant System: Equipped |

1 Unit |

| 3 | Flying Cut-Off Device |

(1) Hydraulic Pump Stand: 1 Set, Auto Start / Stop (2) Hydraulic Cut Modular: 1 Set (3) Modular Material: Cr12Mov (CN Standard) / SKD11 (JP Standard) (4) Length Tolerance: ± 1.0 MM (5) TBI Linear Guideway & Ball Screws: 1 Set (6) Hydraulic Components: Taiwanese (7) Hydraulic Overload Protection Setting: Maxi. & Mini. Pressure, Pump Stand & Forming Machine Stops & Starts, With Wind Coolant System, Filter Function |

1 Unit |

| 4 | Run-Out Table | / | 1 Set |

| 5 | Control System |

(1) Controller: Motion Tracing Controller, Single Axis (2) Touchable Screen: 7” Color Screen, WEINVIEW (3) Encoder: Omron, Japanese (4) Button / Knob: Schneider, France (5) Speed Control: Frequency Converter (6) Power Supplier: 380 V, 50 HZ, 3 Phs; Customized |

1 Set |

LMS Ceiling Tile 600×600 Full Auto Production Line With Film Applicator

Ceiling U Baffle Roll Forming Machine

Ceiling Triangle Grid Roll Forming Machine

Ceiling T Grid T Bar Roll Forming Auto Line

Ceiling Strip Roll Forming Machine

LMS Open Cell Ceiling Grilyato Production Line

Ceiling Furring Roll Forming Machine

Ceiling Carrier Roll Forming Machine

Light Gauge Steel Framing Machine

Please send us roll forming profile with specifications, thickness and other processing requirements for our customized machine.If you need standard machine, please send us the model you want.

Copyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343