Products

Categories

New Products

Brand:

LMSitem no.:

Door Frame Roll Forming MachinePayment:

T/Tproduct origin:

Guangdong, ChinaColor:

Customizedshipping port:

Huangpu, ChinaLead Time:

70 Days

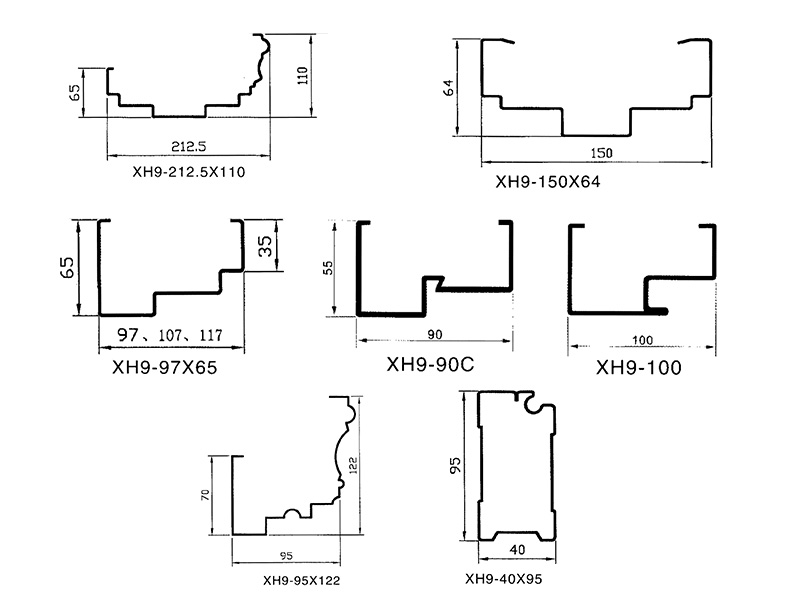

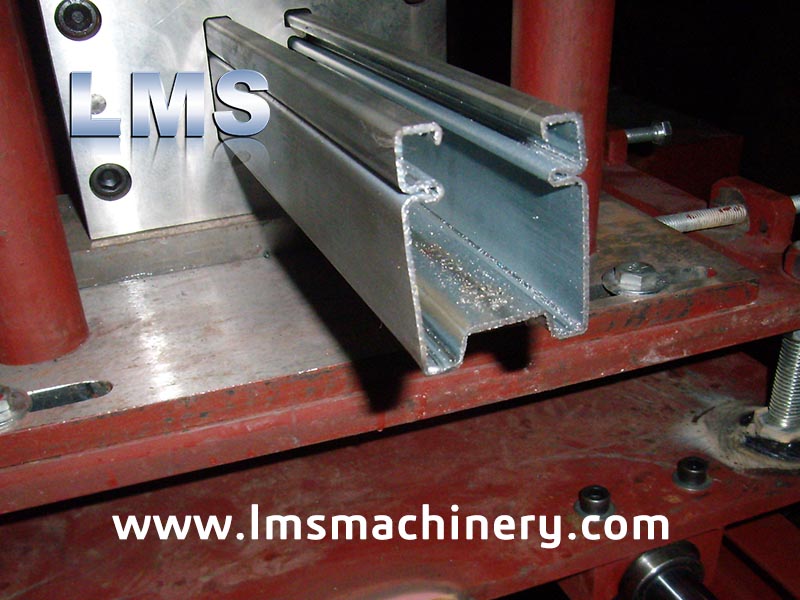

LMS Door Frame Roll Forming Machine With Punching Device mainly consists of decoiler, leveler, hydraulic punch press, roll forming machine, cut-off device, run-out table and electronic control system. Widely used for door frame production in customized dimension and design, LMS Door Frame Cold Roll Forming Machine has the advantage of high production efficiency and accuracy, and stable performance.

Material: CR / G.I. Coil

Material Thickness: 0.8 - 1.5 MM

Quantity Of Forming Rollers: 24 Groups

Roll Forming Speed: 2 - 8 Meters / Minute; Adjustable

Material Coil → Decoiling → Leveling → Hole Punching → Roll Forming → Cut Off → Run Out → Final Profile.

| NO. | Item | Quantity |

| 1 | Decoiler | 1 Set |

| 2 | Leveler | 1 Set |

| 3 | Hydraulic Punch Press | 1 Set |

| 4 | Roll Forming Machine | 1 Set |

| 5 | Cut-Off Device | 1 Set |

| 6 | Run-Out Table | 1 Set |

| 7 | Electronic Control System | 1 Set |

PU Compound Profile Roll Forming Machine

Door Shutter Roll Forming Machine With Punching

LMS Door Shutter Roll Forming Machine

Door Frame Roll Forming Machine

Light Gauge Steel Framing Machine

Please send us roll forming profile with specifications, thickness and other processing requirements for our customized machine.If you need standard machine, please send us the model you want.

Copyright © LMS INTERNATIONAL LIMTED All Rights Reserved. 蜀ICP备17022790号,

川公网安备51010602002262

川公网安备51010602002262

the professional team to service !

86-28-87685256

[email protected]

[email protected] allyrafter

allyrafter 0086 13822 280343

0086 13822 280343